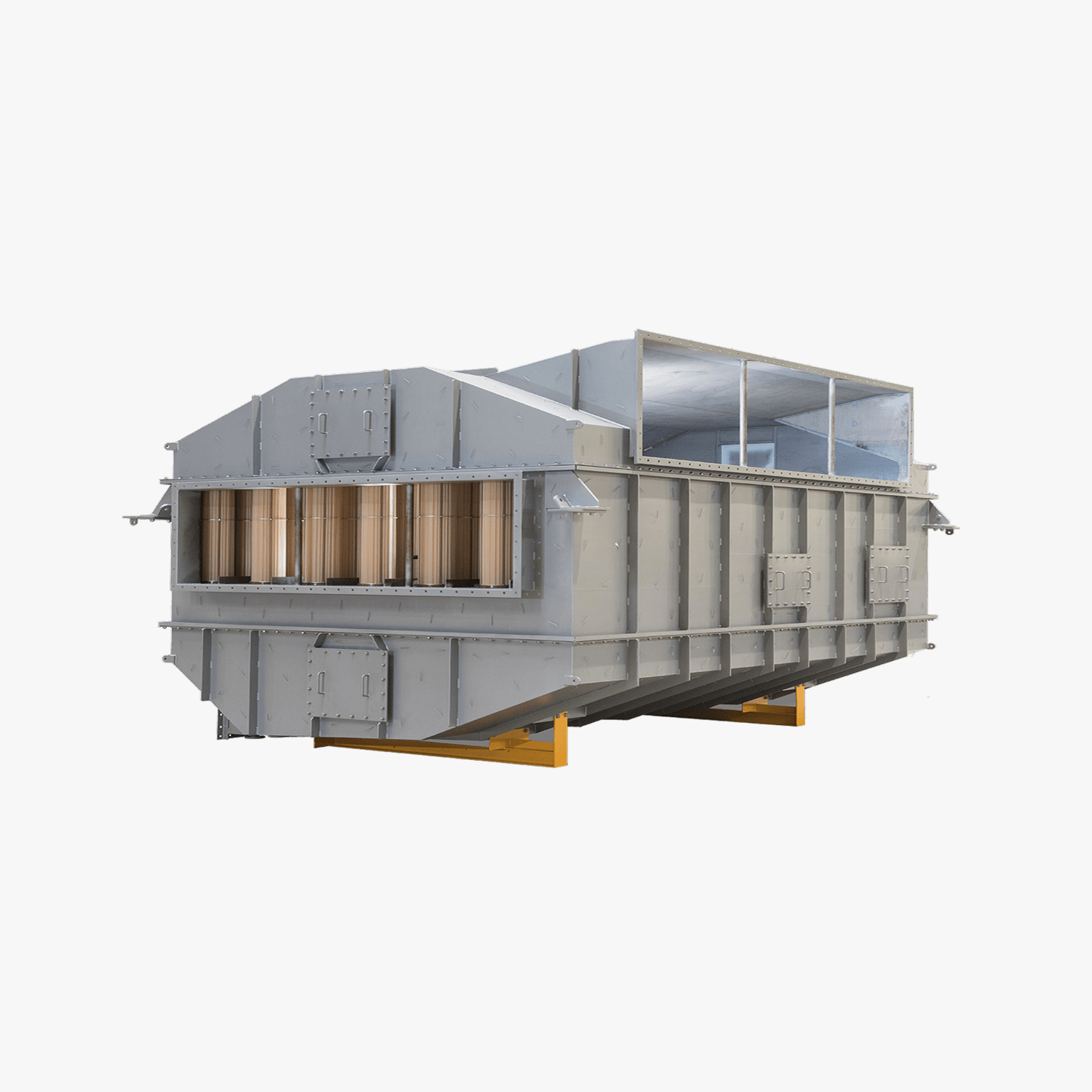

Air Preheater

Efficient heat recovery from process air

An air preheater is a gas/gas heat exchanger that recovers heat from flue gases, baking fumes or drying air to efficiently preheat process, drying or combustion air.

With the air preheater, flue gas heat is integrated directly into the combustion process. Since both flue gas and combustion air are present simultaneously with approximately the same flow rate, this is a very efficient way of heat integration.

Where are air preheaters used?

This type of heat exchanger can be used in various industrial thermal combustion or drying processes.

Engineered for:

- Steam boilers

- Thermal oil boilers

- Dryers

- Furnaces

For the preheating of

- Combustion air

- Drying air

The operating principle of an air preheater

An air preheater (APH) is a gas-gas heat exchanger that recovers heat from flue gases, baking fumes or drying air to preheat combustion air. The flue gas heat is integrated directly into the combustion process. Both flue gas and combustion air are present simultaneously with approximately the same flow rates. Supply and demand move in tandem. An air preheater is therefore an economically attractive way to recover heat. The same principle applies to dryers or furnaces where the air preheater recovers heat from the exhaust air and preheats the intake air.

Benefits and gains

- Higher efficiency through heat transfer between flue gas and process air

- Lower fuel consumption and noticeably higher process efficiency

- Efficiency improvement: 4 to 10% on combustion, up to 25% on drying

Air preheater models

APHs can be made in various configurations

Construction materials

- Carbon steel

- Stainless steel

- Polymer

Air preheater types

- Crossflow tubes

- Counterflow tubes

- Plate exchanger

Cleaning options

- In-line cleaning system

- No cleaning system

ONTWERPKEUZE

What design is the best match for you?

Your specific application requires a tailored design. Is/are your flue gas, baking fumes or drying air clean and dust-free, or is it corrosive and does it contain sulphur or other contaminants? If the wrong design choice is made, maintenance and operational costs will rise, while efficiency falls. Below is an overview of different types of flue gas, baking fumes or drying air and points of interest when it comes to the design.

Your flue gas or drying air is clean

When the air or flue gas is clean, a carbon steel or stainless steel APH is usually sufficient.

Your flue gas is corrosive

In this case, a carbon steel APH will accumulate damage. The acidic components in flue gases condense onto the cold surface of the heat exchanger, which causes corrosion. In this case, a high nickel type stainless steel design is appropriate, such as 316L or 904L. If the flue gases are even more aggressive – for example, due to the presence of sulphur oxides – a polymer APH is necessary.

Your flue gas, baking fumes or drying air is contaminated

Contaminated flue gases require a special APH design as well. Condensation can make the surface wet, causing dust particles to stick. This can lead to contamination of the heat exchanger. An in-line cleaning system can remove this contamination. The result of such a cleaning system is less maintenance and longer service life.

Your flue gases have a high temperature

Some processes emit flue gases at very high temperatures. These situations demand a custom metal APH that takes thermal expansion into account. Heat Matrix is happy to help you make the right choices.

Air preheater by flue gas type

Contaminating flue gases

Air preheater for flue gases containing baking fumes or dusty dry air.

-

MaterialPolymer or stainless steel

-

TypeCounterflow tubes

-

Cleaning Inline

Corrosive flue gases

Air preheater for flue gases containing corrosive elements.

-

MaterialStainless steel

-

TypeCounterflow tubes

-

Cleaning Inline

Natural gas-fired flue gas

Air preheater for flue gases without corrosive or contaminating elements.

-

MaterialStainless steel

-

TypeCrossflow tubes / Plate heat exchanger

-

CleaningManual

Other types of heat exchangers

Besides the air preheater, there are other types of heat exchangers that we regularly use in the heat recovery projects we carry out for clients.

Contact

Curious about your savings potential?

A Heat Recovery Scan gives you quick insight into the most promising concepts for heat recovery, energy savings, reduction of CO2 emissions and payback period.